These handles, characterized by a robust, often angular design, are frequently integrated into various structures, ranging from industrial equipment to sporting goods. Their strength and secure grip provide a significant advantage in demanding applications. For example, machinery requiring substantial leverage or secure attachment may incorporate these handles for enhanced worker safety and operational efficiency.

The inherent strength and secure grip afforded by these handles are crucial in applications demanding high force or secure engagement. Their design often emphasizes durability, resisting wear and tear, and ensuring a reliable hold, even under stress. Historically, similar forms of robust, gripped structures have been used across various industries to improve control and productivity. These improvements contribute to increased safety and reduced errors. The enhanced safety feature benefits users in all contexts where a firm, secure hold is necessary.

This discussion of the functional benefits of these handles sets the stage for a more in-depth exploration of their practical application in different industrial settings. The subsequent sections will delve into the specific types of machinery and industries that commonly utilize these handles, and the critical factors to consider when selecting these components.

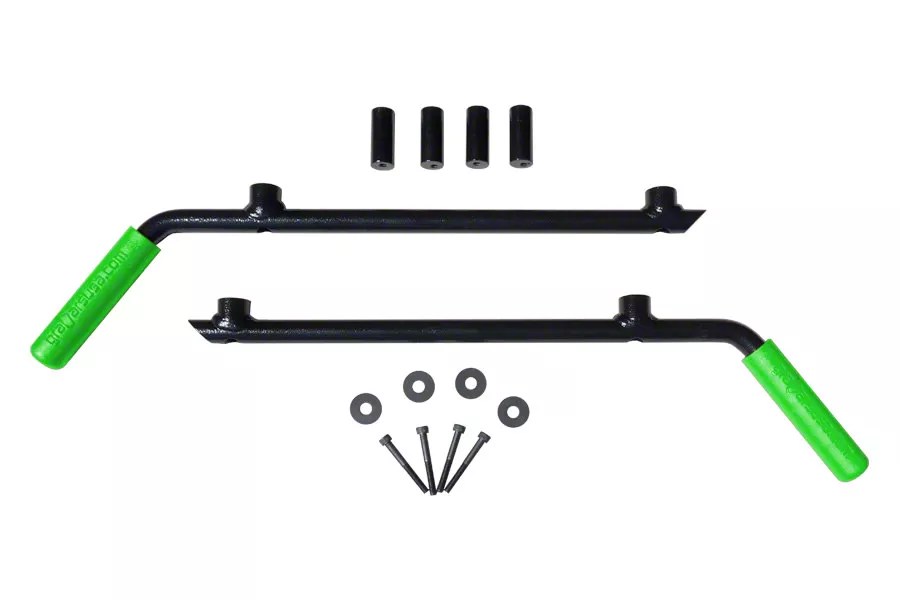

Gladiator Grab Handles

Understanding the key aspects of gladiator grab handles is essential for their effective application in various fields. Design, strength, ergonomics, safety, durability, and cost-effectiveness contribute to their overall utility.

- Robust Design

- Exceptional Strength

- Ergonomic Grip

- Enhanced Safety

- Durable Construction

- Economic Value

Robust design ensures the handles withstand high-force applications. Their strength is critical for heavy-duty machinery. Ergonomic grip promotes user comfort and reduces strain. Enhanced safety features prevent slips and accidents. Durable construction ensures longevity, minimizing replacements. Economic value considers the cost of the handles against the overall operational efficiency they provide. For instance, machinery with these handles might experience fewer accidents and downtime, yielding a substantial long-term return. This balance of design, strength, and cost-effectiveness ultimately maximizes their operational efficiency and workplace safety in diverse contexts.

1. Robust Design

Robust design, a crucial component of gladiator grab handles, dictates their ability to withstand significant stress. This robustness manifests in the material selection, manufacturing processes, and overall structural integrity of the handles. Materials like hardened steel or specialized alloys are often chosen to resist wear, deformation, and fatigue under substantial force. Advanced manufacturing techniques, such as forging or precision machining, contribute to the structural integrity of the handle, enhancing its ability to endure high-impact situations. For example, in industrial machinery operating in harsh environments, robust handles are essential for preventing premature failure and ensuring long-term operational stability. Their design incorporates these elements to ensure extended lifespan and high performance under continuous load.

The importance of robust design extends beyond material selection and manufacturing. Careful consideration of the handle's geometry is critical. A handle's shape, cross-section, and attachment points directly impact its ability to withstand applied forces. Engineers must account for the potential stress points and ensure the handle is structurally sound. Realistic simulations and rigorous testing protocols are frequently employed to verify the handle's resistance to various loads, ensuring its suitability for the intended application. This approach is evident in industries like construction, where the handles must support substantial weight and withstand vibrations during operation. Robust design plays a pivotal role in guaranteeing the safety and efficacy of the entire system.

In summary, a robust design is fundamental to the efficacy and reliability of gladiator grab handles. The selection of appropriate materials, advanced manufacturing processes, and meticulous geometric considerations directly affect the handle's ability to withstand operational stress. This understanding of robust design is critical for maintaining performance, preventing failures, and ensuring worker safety in applications where high forces are consistently applied. Careful consideration of robust design is vital for the long-term viability and safety of any system incorporating gladiator grab handles. It prevents costly repairs, downtime, and potential safety hazards, translating into significant cost savings and enhanced operational efficiency.

2. Exceptional Strength

Exceptional strength is a defining characteristic of gladiator grab handles, influencing their suitability for various applications. This attribute directly impacts the safety and reliability of systems incorporating these handles. Understanding the factors contributing to this strength is crucial for proper selection and application.

- Material Composition and Processing

The materials comprising these handles are specifically chosen for their high tensile strength and resistance to deformation. For example, hardened steel alloys or specialized polymers are frequently employed. Advanced manufacturing processes, such as forging or heat treatment, further enhance the material's strength properties. This meticulous selection and processing contribute directly to the exceptional strength of the handles, ensuring they can withstand considerable stress in demanding operational environments.

- Design Considerations

The design of the handle itself plays a critical role in achieving exceptional strength. Geometric features, such as optimized cross-sections and strategically placed reinforcement, are engineered to resist bending, twisting, and shearing forces. Handle designs often incorporate structural elements that distribute stress across the component, improving overall resistance to failure under load. Real-world applications where this design optimization is significant include heavy-duty industrial machinery and construction equipment, emphasizing the crucial relationship between design and strength.

- Testing and Validation

Rigorous testing procedures are essential in verifying the exceptional strength of these handles. This involves subjecting prototypes and final products to various stress simulations, mimicking real-world operational conditions. Tensile testing, fatigue analysis, and impact resistance tests are common methodologies. Results from these tests provide quantitative data on the handle's ability to withstand specific loads and forces, ensuring they meet the requirements of diverse applications. This validation process minimizes potential operational failures and maximizes the reliability of systems incorporating these handles.

- Impact on Operational Safety

Exceptional strength directly translates into enhanced operational safety. When handles can resist significant force, the risk of breakage or failure under operational loads is minimized. This, in turn, reduces the risk of equipment malfunction, potential injuries to personnel, and costly downtime. Systems incorporating handles with exceptional strength offer greater resilience and reliability, which is paramount in various industries, such as those involving heavy machinery and high-risk operations.

These factorsmaterial composition, design, testing, and safety implicationsdemonstrate the critical importance of exceptional strength for gladiator grab handles. This strength characteristic ensures their reliable performance in challenging environments and significantly contributes to the safety and productivity of the systems they support. An understanding of the correlation between the design elements and the resulting strength allows for informed selection and utilization of these handles.

3. Ergonomic Grip

Ergonomic grip, a key component of gladiator grab handles, directly influences user comfort, reducing strain and fatigue during prolonged or demanding use. Properly designed handles facilitate a secure, natural grasp, minimizing the risk of slips or involuntary releases. This feature is crucial in applications requiring sustained grip, such as industrial machinery, construction equipment, or specialized tools. A well-designed ergonomic grip considers factors like handle shape, size, texture, and the distribution of force to maximize user comfort and minimize the risk of repetitive strain injuries (RSI). This understanding underscores the critical role of ergonomics in minimizing workplace hazards.

The ergonomic design of gladiator grab handles directly impacts user safety and efficiency. Consider a construction worker operating a heavy-duty crane. A handle designed for optimal grip minimizes the risk of the worker losing control of the controls, preventing accidents. Similarly, in industrial environments, ergonomic handles improve worker well-being and safety during prolonged operations. Reduced user fatigue results in improved efficiency and, ultimately, a decrease in production downtime. This translates into cost savings and improved productivity for the organization. Analyzing the specific demands of each application allows for customized design solutions, creating tools that are tailored to minimize physical stress while maintaining high performance standards.

In summary, the ergonomic grip of gladiator grab handles is an essential factor affecting user comfort, safety, and productivity. A focus on ergonomic principles in handle design is crucial for creating tools that minimize the risk of injury and maximize efficiency. Considering factors such as hand size, shape, and the specific forces encountered during operation are essential for creating ergonomic handles that enhance both user well-being and system performance, underpinning the fundamental importance of ergonomic design considerations in all applications involving sustained or repeated hand use. This approach safeguards personnel and ensures optimal system functioning.

4. Enhanced Safety

Enhanced safety is a critical consideration in the design and application of gladiator grab handles. The secure and robust grip offered by these handles directly impacts the safety of users and the overall reliability of systems utilizing them. This section explores the multifaceted nature of enhanced safety, emphasizing its role in preventing accidents and ensuring optimal performance in diverse applications.

- Preventing Slips and Accidents

The primary function of a well-designed grab handle is to provide a secure grip, preventing unintended slippage and potential accidents. This is especially important in high-stress or high-force environments, such as industrial machinery or construction sites. The geometry and texture of a handle directly influence its ability to resist slippage, ensuring users maintain control and preventing falls or injuries during operation. For example, textured surfaces or strategically placed protrusions on the handles of heavy machinery enhance operator grip, preventing accidents and minimizing risk. This direct correlation between grip security and injury avoidance underscores the significance of this facet in safety enhancement.

- Minimizing Risk of Injury

Handles that provide a secure grip reduce the risk of injuries caused by equipment malfunctions or accidents. A strong handle helps maintain control during unexpected movements or impacts, limiting the potential for operator injury. For instance, a handle that allows a worker to maintain a firm grip on a piece of equipment during sudden jolts can reduce the chance of their hands or arms being caught in moving parts. Handles designed with safety in mind thus contribute significantly to a safer working environment.

- Ensuring Consistent Performance

The consistency of grip, as provided by a well-designed grab handle, directly impacts the reliability of machinery. Handles that consistently deliver a firm grip mitigate errors in operation and ensure the intended outcome. A reliable grip allows users to execute tasks efficiently and accurately. This consistency minimizes the risk of dropped loads, misaligned parts, or accidental disruptions in processes. The result is enhanced performance and a decreased likelihood of equipment failures.

In conclusion, the enhanced safety features provided by well-engineered gladiator grab handles extend far beyond mere grip. These handles actively contribute to a safer work environment by preventing slips, minimizing injuries, and ensuring consistent operational performance. Robust design, material selection, and ergonomic considerations are paramount in maximizing safety aspects within any system utilizing these types of handles, fundamentally linking handle design with the safety of those using them and the reliability of the system's performance.

5. Durable Construction

Durable construction is paramount for gladiator grab handles, ensuring longevity and reliability in demanding environments. The ability of these handles to withstand wear and tear directly impacts the operational lifespan of the equipment they serve. This section examines the critical aspects of durable construction, highlighting its significance in various applications.

- Material Selection and Processing

The choice of materials and subsequent processing techniques significantly influence a handle's durability. Materials like hardened steel alloys, high-strength polymers, or composites are selected for their resistance to corrosion, deformation, and fatigue. Advanced manufacturing processes, such as heat treatment or specialized coatings, further enhance the material's inherent strength and resistance to abrasion, thereby extending the handle's operational lifespan.

- Design for Load Distribution and Stress Points

Effective design principles distribute stress evenly across the handle, preventing localized wear or failure. Strategic reinforcement, optimized cross-sections, and the avoidance of sharp stress risers are crucial in achieving high durability. Well-designed handles exhibit exceptional resistance to bending, twisting, and impact forces encountered during everyday use and demanding operational conditions.

- Manufacturing Precision and Quality Control

Precision in manufacturing ensures consistent quality and dimensional accuracy. This meticulous attention to detail across the entire production process directly affects the handle's ability to withstand the stresses of intended use. Rigorous quality control measures, including inspection and testing at various stages of production, guarantee the high-performance standards demanded by these components in applications demanding long-lasting reliability.

- Resistance to Environmental Factors

Handles used in harsh environments require durability against exposure to moisture, chemicals, extreme temperatures, or abrasive particles. Surface treatments, protective coatings, and material selection optimized for the particular application mitigate degradation and ensure sustained performance in demanding conditions. Handles designed for industrial settings, for example, often utilize corrosion-resistant materials or protective coatings to resist environmental wear.

In conclusion, durable construction is essential for gladiator grab handles in ensuring reliability and longevity in various applications. The combination of carefully selected materials, advanced design principles, precise manufacturing techniques, and consideration of environmental factors guarantees the handles maintain their structural integrity and operational effectiveness over extended periods. This, in turn, minimizes maintenance requirements, reduces downtime, and maximizes the overall value of equipment incorporating these crucial components.

6. Economic Value

The economic value of gladiator grab handles extends beyond their immediate cost. A comprehensive assessment considers the total cost of ownership, factoring in factors such as maintenance, downtime, and potential safety incidents. Handles that exhibit durability and reliability translate to reduced replacement costs and minimize the risk of costly equipment failures or work stoppages due to equipment malfunctions. The longevity and consistent performance of high-quality grab handles directly correlate with long-term operational efficiency and cost savings.

Real-world examples illustrate this connection. In industries employing heavy machinery, a robust handle system reduces the frequency of repairs or replacements, lowering the ongoing maintenance budget. Minimizing downtime due to handle failures significantly improves productivity and reduces lost revenue. Additionally, the prevention of workplace injuries, directly linked to the secure grip provided by high-quality handles, translates into cost savings in workers' compensation claims, medical expenses, and reduced lost work time. Consequently, the initial investment in high-quality, durable grab handles ultimately leads to long-term cost savings across various operational aspects. This direct link between quality and cost effectiveness reinforces the importance of careful selection when choosing these crucial components.

Understanding the economic value proposition of gladiator grab handles necessitates a holistic approach that considers their total cost of ownership. This involves assessing not only the purchase price but also the potential for reduced maintenance, minimized downtime, and improved safety. The analysis reveals a direct correlation between the quality of the handles and the long-term financial benefits realized by organizations. Implementing robust procedures for selecting and procuring these handles is a proactive step toward optimized operational efficiency and cost management. This analysis, ultimately, underscores the importance of prioritizing economic value as a critical component in the evaluation process for all equipment purchases.

Frequently Asked Questions about Gladiator Grab Handles

This section addresses common inquiries regarding gladiator grab handles, offering comprehensive insights for informed selection and application. Clear answers are provided to address potential uncertainties and encourage a deeper understanding of these critical components.

Question 1: What distinguishes gladiator grab handles from other types of handles?

Gladiator grab handles are characterized by their robust, often angular design. This distinctive form typically emphasizes strength, secure grip, and durability, making them suitable for high-force applications and demanding environments. Key distinctions may include material composition (often hardened steel or specialized alloys), manufacturing techniques (like forging), and precise geometric design. These features differentiate them from simpler, less robust alternatives, impacting their suitability for different operational conditions.

Question 2: What are the primary benefits of using gladiator grab handles in industrial machinery?

Gladiator grab handles enhance safety and reliability in industrial settings. Their exceptional strength ensures resistance to failure under load, minimizing the risk of equipment malfunction and potential worker injuries. The secure grip they provide prevents unintended slippage and maintains control during high-force operations. These factors, combined with durable construction, lead to increased equipment lifespan and reduced downtime, ultimately contributing to improved operational efficiency.

Question 3: How do ergonomic considerations influence the design of these handles?

Ergonomic design is incorporated to optimize user comfort and reduce strain during extended use. Factors like handle shape, size, texture, and force distribution contribute to a secure yet comfortable grip. This approach promotes operator well-being, minimizes the risk of repetitive strain injuries, and enhances overall productivity.

Question 4: What materials are commonly used in the construction of gladiator grab handles?

Common materials include hardened steel alloys, high-strength polymers, and composites. These choices are driven by the need for high tensile strength, resistance to deformation, corrosion resistance, and fatigue resistance. Specific material selections are frequently tailored to the intended application's environmental factors and required operational stresses.

Question 5: How does the design of these handles ensure durability?

The design aims for consistent load distribution across the handle, preventing localized wear and failure. Optimized cross-sections, strategic reinforcement, and avoidance of sharp stress risers contribute significantly to long-term durability. Handles are often designed with provisions for secure mounting or attachment to the equipment, further ensuring overall reliability and integrity.

Question 6: What are the long-term economic benefits associated with using these handles?

The economic benefits extend beyond the initial purchase price. Reduced maintenance costs, minimized downtime, and fewer safety incidents all contribute to long-term savings. High-quality, durable gladiator grab handles ultimately enhance operational efficiency and lower the total cost of ownership.

In conclusion, gladiator grab handles offer robust solutions for diverse applications, prioritizing safety, performance, and long-term cost-effectiveness. These handles are a key element in optimizing equipment performance, enhancing user safety, and contributing to a more productive work environment. The subsequent section delves deeper into specific application considerations.

Tips for Utilizing Gladiator Grab Handles

Effective application of gladiator grab handles requires careful consideration of various factors. Following these guidelines ensures optimal performance, safety, and longevity.

Tip 1: Material Selection and Compatibility

Appropriate material selection is crucial. Handles must align with the operational environment and the equipment's material composition. Compatibility prevents corrosion, ensures adequate strength, and avoids material incompatibility issues. For example, using a stainless steel handle with a galvanized metal machine might lead to galvanic corrosion, reducing the handle's lifespan and potentially creating safety hazards.

Tip 2: Geometric Considerations

Handle geometry significantly impacts strength and usability. Properly designed geometries distribute forces evenly, minimize stress concentrations, and enhance ergonomics. Consider factors like cross-section, curvature, and surface texture. Handles with sharp edges or inadequate curves can lead to premature failure and cause user discomfort.

Tip 3: Attachment and Mounting Procedures

Secure attachment is paramount. Follow manufacturer guidelines meticulously for mounting procedures. Improper installation compromises the handle's structural integrity, potentially leading to failure under load. Ensure correct torque values and use appropriate fasteners to prevent loosening and ensure a reliable connection.

Tip 4: Ergonomic Design Principles

Ergonomic design enhances usability and minimizes operator fatigue. Consider factors like handle size, shape, and surface texture. A well-designed handle promotes a secure grip, reducing the risk of slips and injuries during demanding tasks. A poor ergonomic design can contribute to musculoskeletal disorders, leading to lost productivity and safety issues.

Tip 5: Environmental Considerations

Environmental factors play a role in the lifespan of the handles. Exposure to chemicals, moisture, or extreme temperatures can degrade materials. Handle selection should take into account the specific environmental conditions in which the equipment operates. Consider using specialized coatings or materials resistant to the prevailing environmental stressors.

Tip 6: Regular Inspection and Maintenance

Regular inspection is critical to identify potential issues early. Visual inspections for damage, cracks, or signs of wear are essential. Prompt identification of wear and tear or defects extends the operational life of the system and minimizes risks. Addressing potential problems early can prevent costly breakdowns and ensure operational safety.

Adherence to these tips maximizes the operational lifespan, minimizes potential hazards, and optimizes the overall performance of the equipment utilizing gladiator grab handles. Implementing these strategies is essential for both safety and efficient functionality in any demanding application.

The subsequent sections delve deeper into specific case studies and practical application examples, providing a detailed understanding of how to appropriately select and utilize these handles in diverse environments.

Conclusion

This exploration of gladiator grab handles reveals a multifaceted component crucial for operational efficiency and safety. Robust design, exceptional strength, ergonomic considerations, and durability are foundational elements. The enhanced safety afforded by a secure grip, minimizing the risk of accidents and injuries, is a key benefit. These handles' economic value is also significant, as durable construction translates to reduced maintenance, minimized downtime, and extended lifespan, ultimately contributing to cost savings. The analysis highlights the importance of selecting these components based on rigorous criteria to match specific application needs. Material selection, geometric optimization, and proper mounting procedures are critical for reliable performance and extended operational life.

The application of gladiator grab handles extends across various industries. Selecting the appropriate handle type for specific machinery and operating conditions is paramount. Thorough understanding of application-specific demands, coupled with adherence to manufacturer guidelines and maintenance protocols, optimizes the benefits of these crucial components. Continuing research into material advancements and design innovations ensures future improvements in strength, ergonomics, and durability. Ultimately, prioritizing safety, reliability, and economic viability ensures the effective use of these handles, contributing to optimal operational efficiency and a safe working environment.

You Might Also Like

Antenor Mayrink Veiga: Top Stories & NewsHappy Birthday, November 14th Born!

Epic Action & Adventure With TheActionJunkie!

Jayalalithaa & Sobhan Babu: A Powerful Duo?

AI-Generated Actress Images: Stunning Visuals & Creative Art

Article Recommendations

- Mastering The Art Of Your So A Comprehensive Guide

- Cole Holcomb Injury Update Latest News Status

- Dbacks Announcers Best Voices In Arizona Baseball